Molten Collection

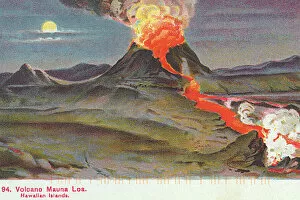

"Molten: The Fiery Essence that Shapes Worlds and Industries" Witness the raw power lava as it erupts from Mauna Loa Volcano

All Professionally Made to Order for Quick Shipping

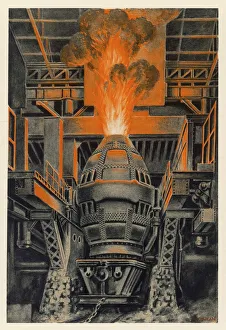

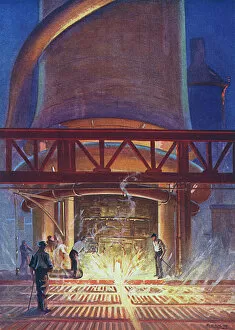

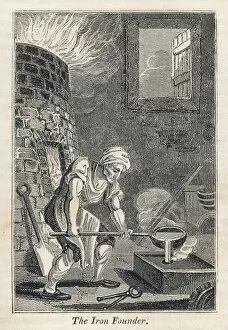

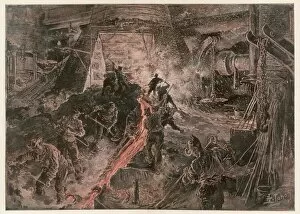

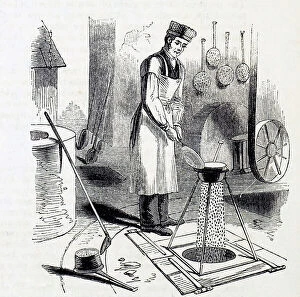

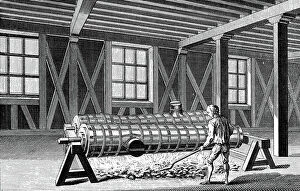

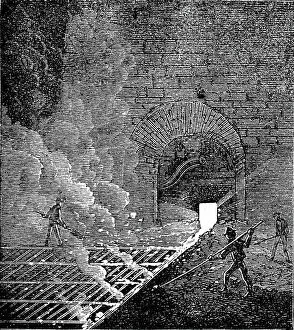

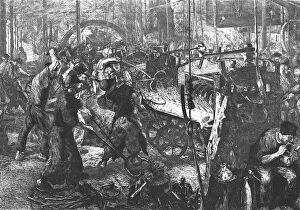

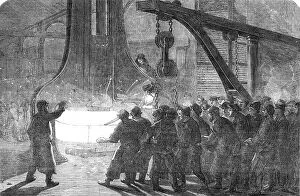

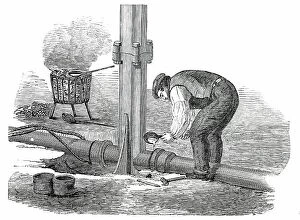

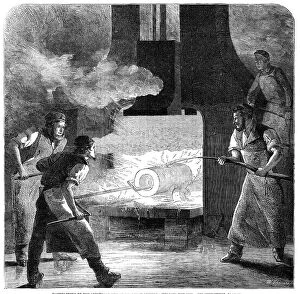

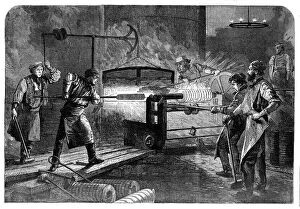

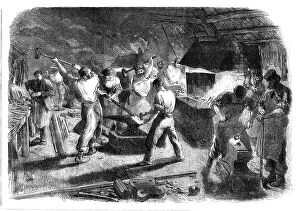

"Molten: The Fiery Essence that Shapes Worlds and Industries" Witness the raw power lava as it erupts from Mauna Loa Volcano, one of the most active volcanoes in the Hawaiian Islands, USA. Step back in time to the 1800s British factories where skilled artisans blew glass into exquisite shapes using molten glass, creating timeless works of art. Delve into the world of glass factory workers in Britain during the 1800s, as they skillfully manipulated molten glass with precision and expertise. Explore Longwy steelworks in France and marvel at the Bessemer converter's transformational process, turning liquid metal into sturdy steel for various industries. Uncover how molten metals shape our modern world by delving into their role within industries such as manufacturing, construction, and transportation. Journey deep beneath Earth's surface to discover how molten materials form planets' internal structures – a mesmerizing dance between heat and pressure over millions of years. Brace yourself for an infernal experience as we delve into HELL itself – a metaphorical representation where intense heat turns everything to molten chaos. Experience firsthand the awe-inspiring sight of a blast furnace roaring with flames at full capacity within a bustling steelworks facility – an embodiment of industrial might. Immerse yourself in Birmingham Ironworks' rich history dating back to 1827 when iron founders harnessed molten iron's potential to fuel industrial progress on a grand scale. Behold nature's own fiery spectacle - witness a mesmerizing lava lake bubbling with red-hot intensity amidst Africa's volcanic landscapes; truly an unforgettable sight. Explore how iron foundries played a pivotal role during the Industrial Revolution by harnessing immense heat to transform raw materials into essential components for machinery and infrastructure.