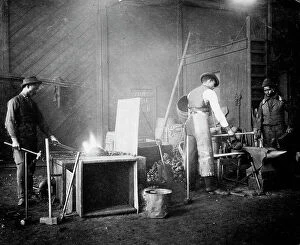

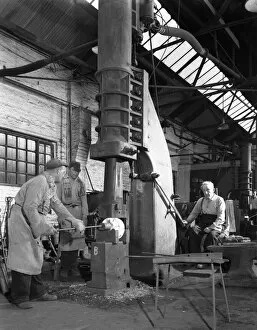

"Steelworker: The Backbone of Industrial Progress" From the dizzying heights of the Empire State Building in 1931 to the bustling foundries of South Yorkshire in the 1960s, steelworkers have played a pivotal role in shaping our world. These unsung heroes fearlessly treaded upon girders, their silhouettes etched against the New York City skyline as they constructed an architectural marvel that would stand tall for generations. In Wombwell Foundry, South Yorkshire, circa 1963, a skilled pattern maker named Michael Walters meticulously crafted intricate molds that breathed life into molten metal. His artistry and precision ensured that every piece produced was not just functional but also visually captivating. Meanwhile, at AT Green & Sons Ltd in Rotherham, South Yorkshire, steelworkers forged with unyielding determination. Sparks flew as they shaped raw materials into robust structures that would withstand immense pressure and bear heavy loads. Their craftsmanship formed the backbone of industries across Britain. The bar mill at Brightside Foundry in Sheffield stood as a testament to both innovation and hard work. In 1964, it hummed with activity as steelworkers maneuvered colossal machinery to produce high-quality bars essential for construction projects worldwide. Their dedication fueled progress and propelled nations forward. Artists like Gustav Klutsis captured the spirit of these industrious men through powerful imagery. From his iconic poster urging workers to turn a five-year plan into four years to his depiction of miners laboring underground amidst charcoal darkness in 1908 – Klutsis celebrated their resilience and unwavering commitment towards building a better future. Across continents, from Homestead Pennsylvania's Russian Boarding House to workshops where showers of sparks illuminated determined faces - steelworkers embodied grit and perseverance. They embraced danger daily while forging metals or operating complex machinery because they understood that their efforts were integral to society's advancement.