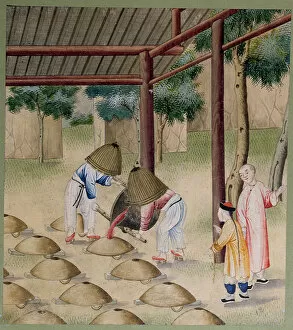

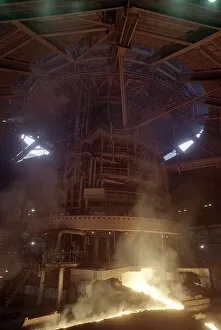

Molten Metal Collection

"Molten Metal: A Glimpse into the World of Iron Foundries and Traditional Forges" Step back in time to 1924

All Professionally Made to Order for Quick Shipping

"Molten Metal: A Glimpse into the World of Iron Foundries and Traditional Forges" Step back in time to 1924, where the J Shop - Iron Foundry stands as a testament to craftsmanship and industry. With sparks flying and heat radiating, skilled workers forge molten metal into magnificent creations. In a mesmerizing scene captured on paper, we witness the artistry involved in working at a traditional forge. The glow illuminates their faces as they shape it with precision and skill. Delve deeper into England's industrial history with "The Wealth of England: the Bessemer Process of Making Steel. " This groundbreaking technique revolutionized steel production, propelling Britain forward as an industrial powerhouse. Transport yourself to The International Railway Congress through a captivating black-and-white photograph. Amidst towering machinery, molten metal flows like liquid fire while Mr David Ennals MP explores the forge shop, witnessing firsthand the power behind our nation's defense. Five dedicated workers carry holders inside an iron foundry's interior. Their strength is matched only by their determination to mold molten metal into functional works of art that will withstand time itself. Travel even further back in time with "The Silversmith" engraving from 1718. Witnessing this age-old craft reminds us that molten metal has been shaped by human hands for centuries, creating timeless treasures that captivate hearts across generations. Hartman Schopper's woodcut publication takes us on another journey – this time alongside "The Letter Plate Maker. " In his workshop filled with tools and raw materials, he transforms ordinary metals into extraordinary pieces that adorn doors worldwide. An artwork depicting an iron-smelting furnace transports us to its fiery core – where temperatures soar high enough to melt solid rock. Here lies the birthplace of molten metal; its transformational journey begins within these scorching walls. Marvel at modern-day heroes, the metalworks foundry workers.