Mems Collection

"Exploring the Intricate World of MEMS

All Professionally Made to Order for Quick Shipping

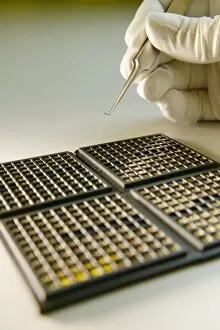

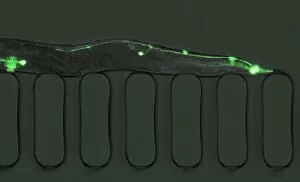

"Exploring the Intricate World of MEMS: From Factories to Artwork" Step inside the fascinating realm (Micro-Electro-Mechanical Systems) as we unveil the captivating journey from production to quality control. 🏭🔬 At MEMS factory C013 / 5614, cutting-edge technology intertwines with innovation, giving birth to remarkable devices that push boundaries. Witness the intricate craftsmanship in MEMS devices artwork C013 / 5615, where creativity meets precision. Delve deeper into this microcosm and discover the heart of it all – the MEMS chip. Behold its composite artwork at C013 / 5611 and marvel at its complexity. But how are these chips made? The answer lies within MEMS factory C013 / 5612, where meticulous processes like metal evaporation and chemical etching bring them to life. Every detail matters in this world of miniaturization. External connections play a crucial role in ensuring seamless functionality during production. Witness their integration firsthand. The magic doesn't stop there; machined silicon wafers take center stage during production at MEMS factory C013 / 5610. These wafers undergo furnace processing, transforming raw materials into technological wonders. But what about quality control? Fear not. At every step along this mesmerizing journey, stringent measures ensure perfection is achieved. Precision is paramount when it comes to guaranteeing flawless performance. MEMS – an amalgamation of science and artistry that captivates our imagination while revolutionizing industries worldwide. So next time you encounter these tiny yet mighty wonders, remember the immense effort behind their creation.