Chemical Plant Collection

"Unveiling the Industrial Marvel: Exploring the Chemical Plant of Muscle Shoals, Alabama" Step into a world where science and innovation converge

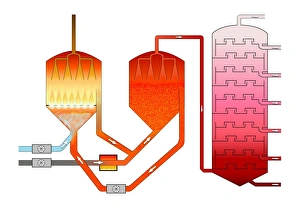

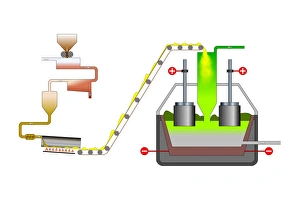

All Professionally Made to Order for Quick Shipping

"Unveiling the Industrial Marvel: Exploring the Chemical Plant of Muscle Shoals, Alabama" Step into a world where science and innovation converge, as we delve into the captivating realm of a chemical plant nestled in the Backwaters. Witness the Residfiner at an oil refinery tirelessly working to refine crude oil, ensuring its transformation into valuable resources. Behold the colossal storage tanks that stand like sentinels, safeguarding precious chemicals waiting to be utilized in various industries. Here, every drop counts and is meticulously stored for future use. Meet an unsung hero - an oil refinery worker whose dedication fuels this thriving hub of progress. With unwavering commitment and expertise, they navigate through intricate processes to keep operations running smoothly. Immerse yourself in history as we transport you back to 1942 when Alfred T Palmer captured these mesmerizing moments. Gaze upon the Electric Phosphate Smelting Furnace used in crafting essential elements that shape our modern lives. Marvel at TVA's chemical plant rising from its smokestacks; it is here that elemental phosphorus comes alive amidst a backdrop of industrial prowess. Witness firsthand how this vital substance is harnessed with precision and care. The grandeur continues with a glimpse of a large electric phosphate smelting furnace dominating Muscle Shoals' landscape. This mighty machine stands tall as it plays an integral role in producing crucial elements that power countless industries. Intriguingly mysterious yet undeniably awe-inspiring, this chemical plant serves as a testament to human ingenuity and scientific advancement. It symbolizes our relentless pursuit of progress while honoring nature's bountiful offerings. Join us on this captivating journey through time and witness how one facility can transform raw materials into wonders that shape our world – all within the walls of this remarkable chemical plant.