Biringuccio Collection

"Biringuccio: Mastering the Art of Metallurgy and Pyrotechnics in 1540" Step into the world of Biringuccio, a brilliant innovator ahead of his time

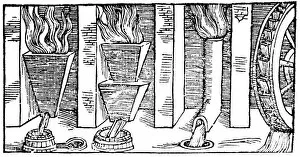

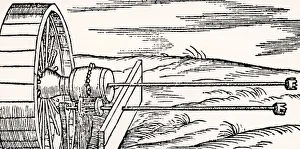

All Professionally Made to Order for Quick Shipping

"Biringuccio: Mastering the Art of Metallurgy and Pyrotechnics in 1540" Step into the world of Biringuccio, a brilliant innovator ahead of his time. In an era where charcoal burning was essential for fuel, he revolutionized the process with his expertise. With bellows in hand, he skillfully increased the draught in furnaces to achieve optimal results. But Biringuccio's genius didn't stop there; he delved into blast furnaces, exploring their different forms and harnessing their power. Utilizing overshot water wheels to power bellows, he elevated metallurgical practices to new heights. Refining copper became an art under Biringuccio's guidance as he employed bellows once again to intensify the furnace's draught. Notably, cupellation played a crucial role in this process - a testament to his meticulous attention to detail. Charcoal burning took on a whole new dimension as Biringuccio constructed pyramids of wood covered with bracken and earth. This innovative technique ensured efficient combustion while minimizing waste. Intriguingly, Biringuccio even ventured into weaponry advancements. He crafted molds for fire tubes fired from cannons at enemy forces - an ingenious tactic that changed warfare forever. Pikes and lances fitted with small fire tubes propelled fiery missiles towards adversaries with devastating impact. The machinery behind cannon production fascinated him too; shafts of cannon boring machines equipped with drilling bits showcased his dedication to precision engineering. Alongside these impressive contraptions stood two-man treadmills tirelessly powering them forward. Boring cannons became another area where Biringuccio left his mark - refining techniques that would shape military history forever. His relentless pursuit of innovation knew no bounds as he constantly sought ways to improve upon existing technologies. From De la pirotechnia by Vannoccio himself emerged vivid depictions of fire tubes being launched at enemy cavalry from cannons.